Advantage 1: Good shock absorption effect

The airbag suspension can provide a good

shock absorption effect for the vehicle. This utilizes the compressibility of

the air. The airbag suspension can achieve a "soft connection"

compared to the steel plate suspension. The deformation of the airbag is faster

and superior than that of the steel plate. The airbag suspension can provide

good shock absorption for the vehicle.

The airbag vehicle has a good shock

absorption effect, and is often used in vehicles that transport some goods such

as glass and precision instruments. In recent years, domestic truck drivers

have increased the comfort requirements of vehicles. Many vehicles that

transport ordinary cargo have begun to use airbag suspension, and the airbag

suspension brings more than comfort to the owner.

Advantage 2: More fuel saving

It is said that the vehicle with the airbag

suspension will be more fuel-efficient. It is estimated that many people will

not understand why, but let me talk about how the airbag suspension can save

fuel.

For example, when the vehicle walks to a

bumpy road, should it slow down slowly? At this time, if the vehicle is

suspended by the airbag, it can pass the bumpy section without deceleration or

a small deceleration.

After the vehicle decelerates, it needs to

accelerate to the normal speed. This process needs to consume more fuel. The

airbag suspension has good shock absorption capability, which allows the

vehicle to pass quickly, and minimizes the impact of the bumpy road on the

speed of the vehicle. It will save fuel.

Advantage 3: Protect the chassis

components

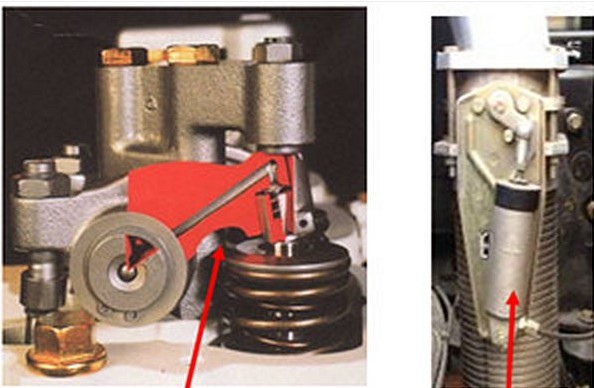

Thanks to the good damping effect of the

airbag, the vibration from the road surface can be minimized, the damage to the

chassis components due to vibration can be minimized, and the looseness of the

screws on the chassis can be avoided. For the simplest example, the airbag

suspension will greatly reduce the chances of the trailer being opened. Import

trucks are very durable, in part because they use airbag suspension.

Advantage 4: Convenient hanging transport

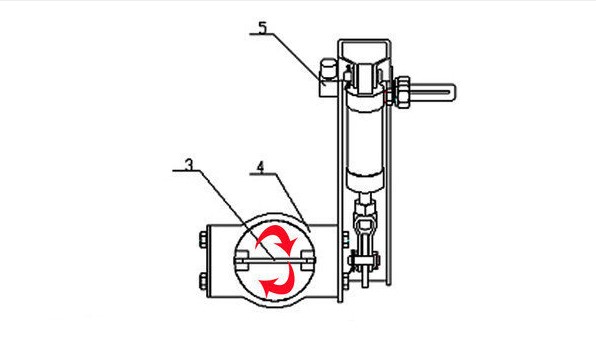

The airbag-suspended tractor makes the

sling transport faster. The ECAS system can be used to quickly adjust the

height of the airbag, and the fastest connection and detachment can effectively

reduce the number of swaying the trailer legs. It is precisely because of the

convenience of hanging transport, more and more logistics companies are now

using airbag suspension.

Advantage 5: Facilitate loading and

unloading of goods at different heights

Today's vehicles need to stop at the

platform for loading and unloading goods. There will be gaps in the platform

height of different goods yards, which may cause inconvenience to the forklift

or the land cows entering the vehicle for loading and unloading goods. If the

vehicle is equipped with an airbag suspension, the height of the airbag can be

adjusted so that the height of the vehicle's cargo box is consistent with the

height of the platform to facilitate loading and unloading.

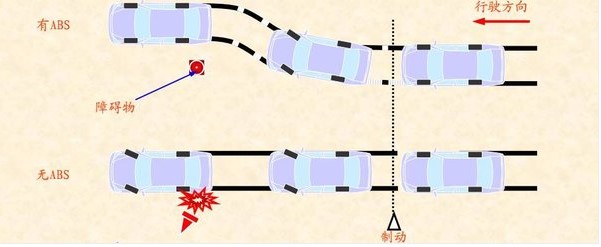

Advantage 6: Save tire protection pavement

Because the airbag suspension is a

"soft link" when the vehicle is driving on a road with poor road

surface, the tire fits well with the road surface, and does not cause the tire

to be in contact with the road surface to accelerate the wear of the tire like

a leaf spring. Therefore, the airbag suspension can reduce the wear of the

tire. At the same time, thanks to the "soft link" of the suspension

of the airbag, the tire will have much less damage to the road surface and can

also protect the road surface.