Step 1: Surface treatment for raw material

The titanium alloy or 304 stainless steel material should be brushed on the surface after the pipe forming, and then sandblasted. So that the purpose is to better adsorb on the product when coating ceramic, and will not fall off.

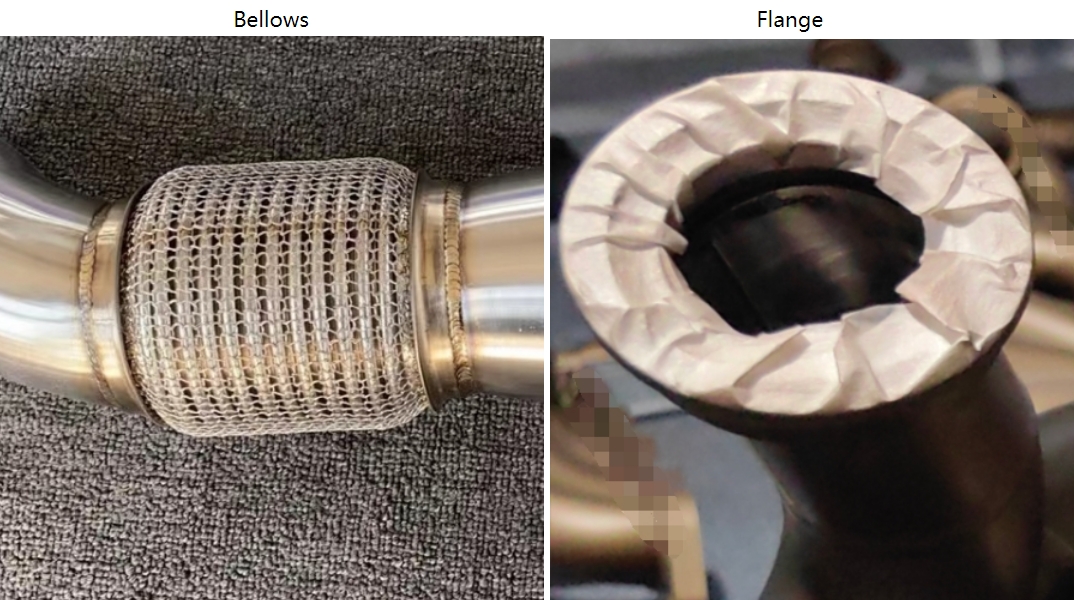

Step 2: Protection accessories

Protect the bellows and flanges to avoid being coated with paint when coating ceramic,then cleaned surface.

Step 3: Surface baking

It can be air-dried or placed in the oven to bake (faster efficiency).

Step 4: Ceramic spray paint,then baked

Bulk purchase of imported coated ceramic raw materials, the price is better. And our coated ceramic have the below advantages:

- It can withstand extreme high temperatures and maintain stable physical structure and performance even in high temperature environments

- High chemical stability, able to resist acid and alkali corrosion, suitable for use in harsh environments

- Good wear resistance, corrosion resistance and thermal stability, and longer service life than traditional materials

- The surface is smooth, the color is uniform, and it is not easy to fade or age in high temperature and corrosive environment